How to prepare a Raid

Winterizing your Rib and Outboard Engines – Part II

How to prepare a Raid

Winterizing your Rib and Outboard Engines – Part II

Winterizing your Rib and Outboard Engines – Part I

Please, do not abandon your passion!

The water, and especially the saltwater, corrodes everything while the immobility accelerates the wear.

The above phrase speaks by itself and there is no room for doubt. So, when the leaves of the trees begin to fall, it’s time to start thinking about preparing the hibernation of your rib and engines.

Their proper maintenance for the long winter immobility will save you from further damage and cost while the possibility of losing a valuable next season’s excursion will be minimized.

This content is for Basic and Premium members only.

Read more Topics

- October 27, 2023

Why HYDROTAB’s Interceptors lead the competition!

Innovation is a key element of development and a determining factor for the success of any product. When it is characterized by the simplest operation combined with the best quality of construction...

Read more - October 18, 2022

Twin 600hp Verados Versus Triple 400R Verados

At the 61st Genoa Boat Show we had the opportunity to test the new beastly 7.6-liter, V12 and 600-horsepower Verado outboards mounted on the MAR.CO R-Evolution 36, a...

Read more - October 18, 2022

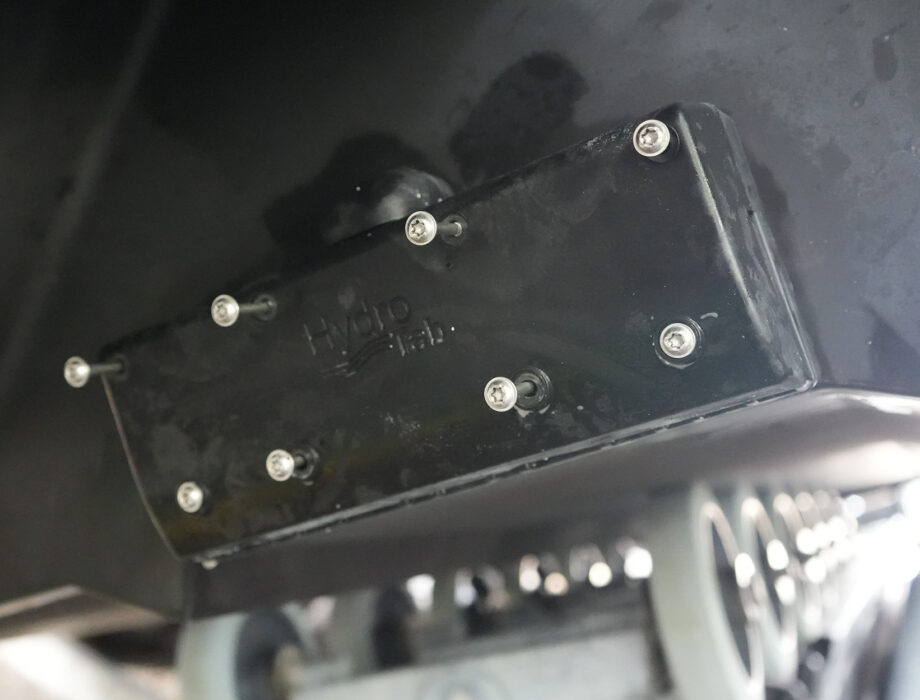

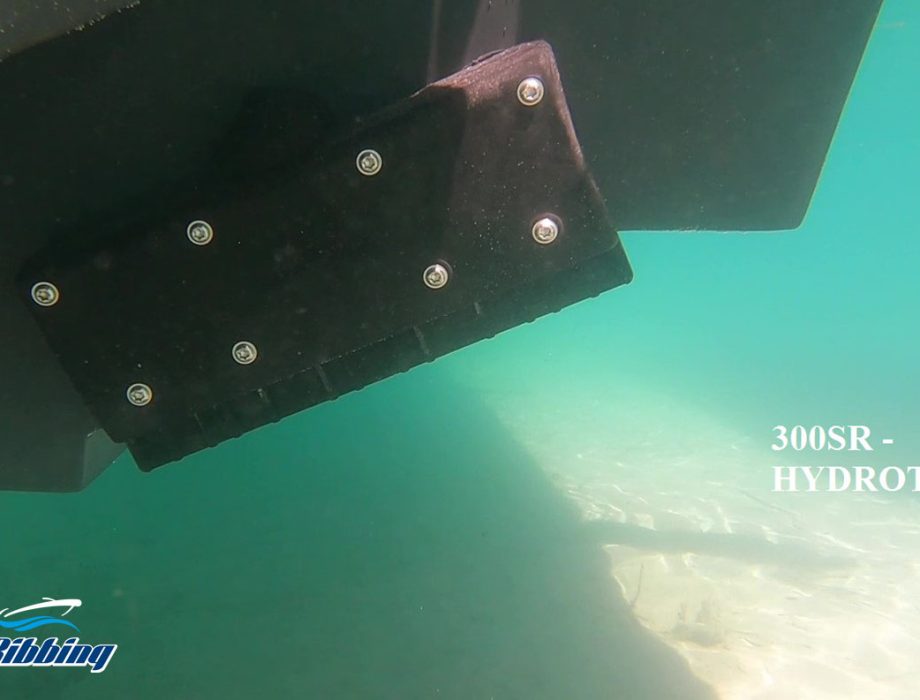

Testing Hydrotab’s new composite 300SR trim tabs in combination with the new Moby automatic controller

As we have already mentioned in our related articles, the use of trim tabs is of great importance on each Rib...

Read more - October 17, 2022

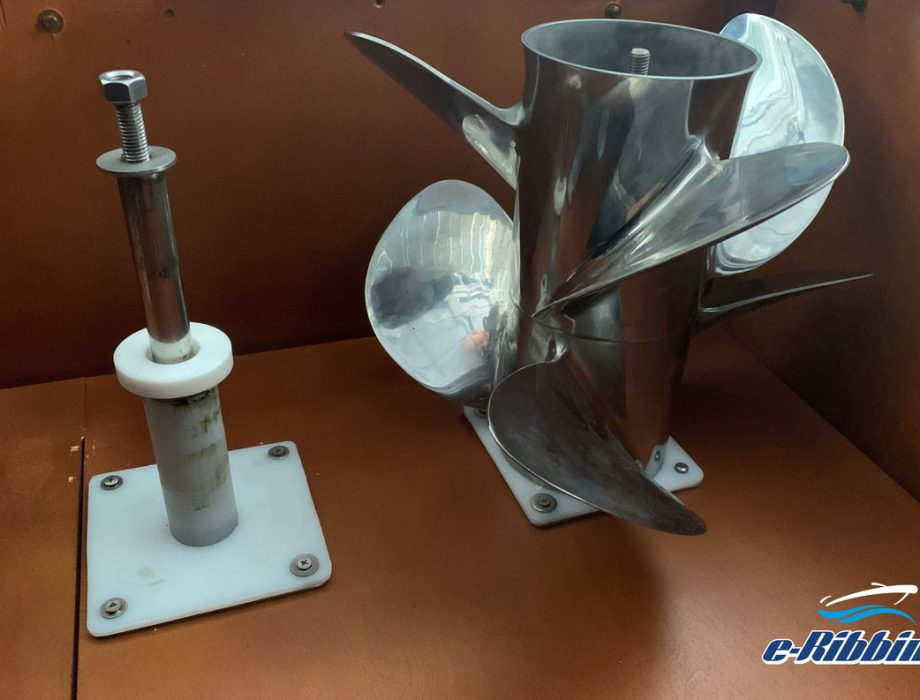

Storage of the spare propeller

It is a fact that a spare propeller is one of the most important elements of the basic equipment of every boat and is really important for our safety, especially if we are used to making long...

Read more - October 17, 2022

Storing our stern anchor inside the boat

There is no doubt that a stern anchor is one of the basic supplies that we shall always have on board and therefore one of the elements of the necessary equipment that every boat...

Read more - October 17, 2022

Solar panels on board

It is true that lately the inflatable boats have grown up to 50 feet in length. As a result, their equipment, such as refrigerators, freezers, heaters, microwaves, etc., have also

Read more - October 17, 2022

Single vs Twin engine Ribs – Pros and Cons

One or two outboard engines? That’s an essential dilemma that concerns many sea-friends who have decided to buy a larger rigid inflatable boat. And the answer is...

Read more - October 17, 2022

How to buy a RIB (Rigid Inflatable Boat)

Do you want to buy a rigid inflatable boat (RIB) but you do not know how to go about it? Worry no more. This article will guide you on what to consider in making the best possible...

Read more - October 17, 2022

How to Set-up our Rib properly

It would not be an exaggeration if we said that it is wonderful and sometimes even fascinating to have the required basic knowledge so as to be able to setup a boat...

Read more - October 17, 2022

Unbelievable hulls that «flatten» heavy seas!!!

It is true that we often hear about «great» captains who «flatten» the waves with their unbelievable Ribs, even waves created by winds of 7 or 8 bf. Of course, they never talk...

Read more - October 17, 2022

Useful tips for restoring a Rib

Every year we have always the same problem: “how can I clean my Rib without damaging its tubes’ surface?” Here it is a complete tutorial for the restoration of your inflatable boat...

Read more - October 17, 2022

Few useful tips for towing a boat Trailer

Each time we are going to tow our Rib, it is necessary to check thoroughly the trailer to ensure not only our own safety but our beloved inflatable boat as well...

Read more - October 17, 2022

Winterizing your Rib and Outboard Engines – Part II

Having completed the maintenance of your engines, which must remain in a vertical position in order to drain well from the water, we proceed to the maintenance of the Rib...

Read more - October 13, 2022

Winterizing your Rib and Outboard Engines – Part I

Please, do not abandon your passion! The water, and especially the saltwater, corrodes everything while the immobility accelerates the wear...

Read more - October 13, 2022

How to prepare a Raid

The word «raid» has the power to bring to mind mysterious islands and unlimited rides to every devotee of ribs deserving this title...

Read more - October 13, 2022

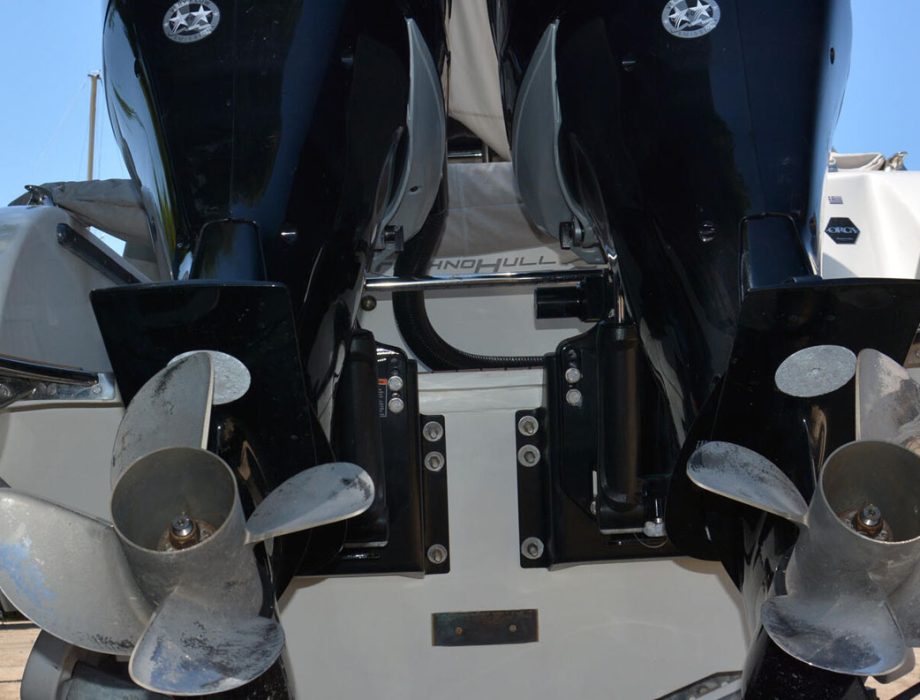

Can we control the prop’s stern lift with the Jackplate’s help?

Many of us, at the chase of the ideal propeller, have tried quite many of them looking for the ideal one for our rib-engine combination...

Read more - October 13, 2022

Benefits of Hydraulic Jack Plate

As it has already been mentioned, there is no the ideal engine height suitable for any combination of hull, prop and load but each...

Read more - October 13, 2022

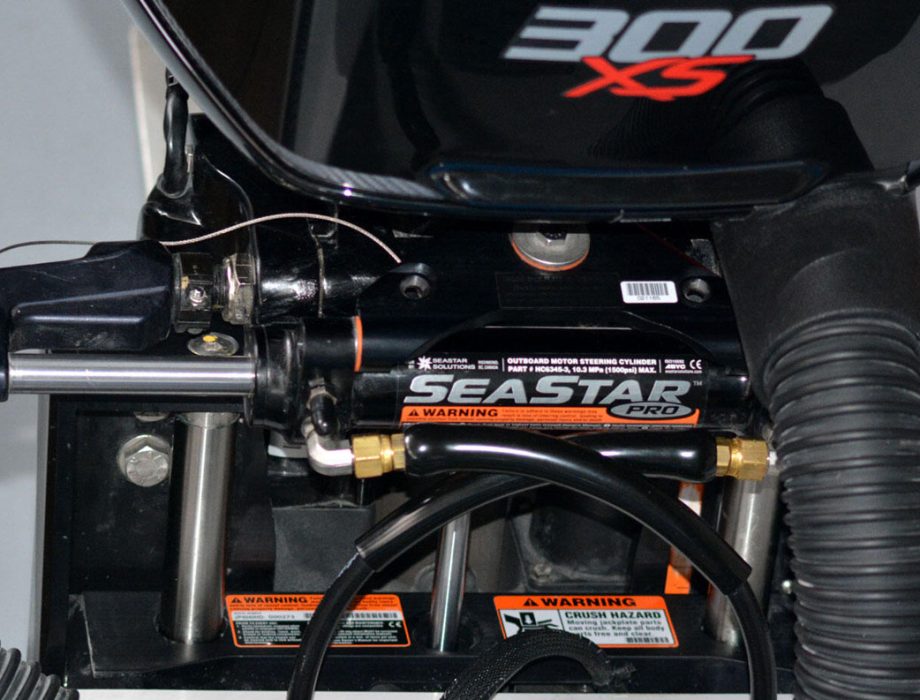

Annual Maintenance and Regular Inspections of the hydraulic steering system

Every year about this time, boaters across the country start to get the itch. The days get a little longer, and a little warmer, and it just..

Read more - October 13, 2022

How to Maintain Your Boat’s Steering Cables

I’ve heard steering cables should be «maintained». How exactly is this done?

Read more - October 13, 2022

Spring Boat Maintenance Tips

As spring slowly approaches, it’s time to start planning for boating season. In order to make sure your boat is safe and running efficiently...

Read more - October 13, 2022

Check and take care of your RIB and engine every time you get out of the sea

Taking into consideration the ancient Greek saying «Prevention is better than Cure», it would be appropriate to check our RIB and our engine every time we get out of the sea. It...

Read more - October 13, 2022

Moving the engine just one hole up or down can have a huge affect on boat’s performance

As we have seen in the previous article entitled «Engine’s mounting heigh», one of the most important factors affecting a lot the boat’s performance is the engine’s mounting...

Read more - October 13, 2022

Suzuki’s Lean Burn Control System: Go further, faster, for less

Nowadays, as the increase of the cost of fuel has become one of the major factors for the choice about the proper outboard, Suzuki has

Read more - October 13, 2022

Trim Tabs should be mounted in the proper negative angle

As we have seen in a previous article, the trailing edge of the trim tabs should be slightly higher than their front edge when they are fully retracted. This slight upward...

Read more - October 12, 2022

Useful tips for improving our fuel mileage

The lower the fuel consumption is the happier the captain gets. Saving fuel is an issue that «burns» all of us...

Read more - October 12, 2022

The Maritime knots and their use II. The Cleat hitch and the Highwayman’s hitch

The Maritime knots and their use II. The Cleat hitch and the Highwayman’s hitch...

Read more - October 12, 2022

The Maritime knots and their use. The Bowline and the Clove Hitch

Before we go out to the sea with our boat, it is necessary to know some basic knots that will mainly help us to tie with safety...

Read more - October 12, 2022

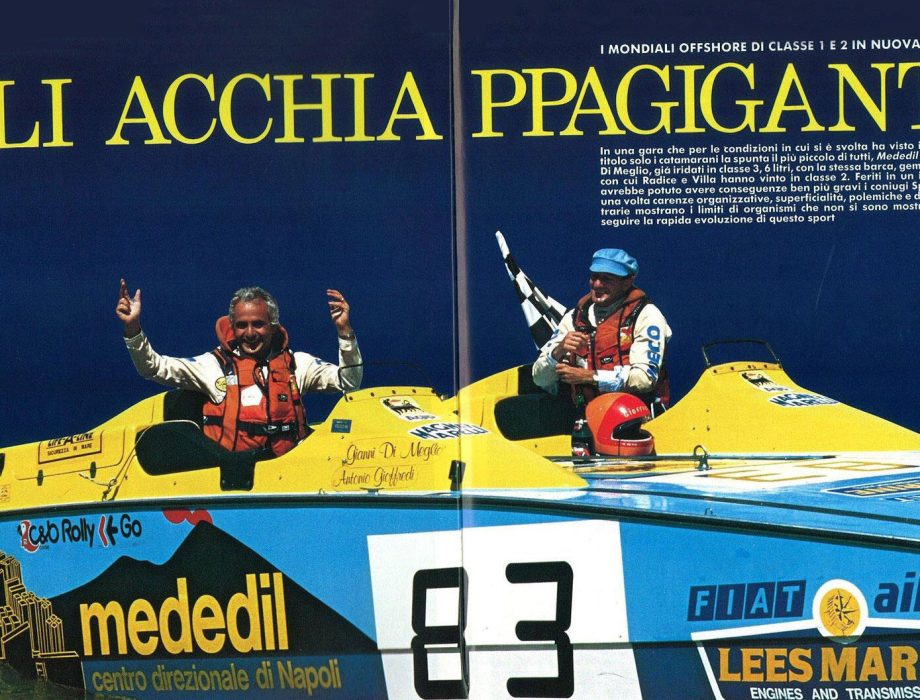

Full throttle with a Neapolitan Legend in Offshore powerboat racing!

A few days ago we had the joy to meet Gianni Di Meglio, one of the most famous offshore powerboat racers in Italy and…not only. Any...

Read more - October 12, 2022

Soffio 31… the flying Rib!

This project was born some time ago in the one of the most beautiful places of our beloved Italy, standing in the wonderful...

Read more - October 12, 2022

Installing an extra fuel supply system

Any obstacle to the constant flow of fuel from the tank to the engine is sure to immobilize us. It is indeed...

Read more - October 12, 2022

The right choice of trim tabs and their proper placement

As we have seen in previous articles, the application of trim tabs is particularly useful to any boat. They improve hole shot, boat’s...

Read more - October 12, 2022

10 useful Tips for safe Trips

Perhaps there is nothing more exciting than the time we take our place behind the cockpit, our hand pushing the throttle and the bow...

Read more - October 12, 2022

Preserving a bright and shiny hull

It is known that the outer surface of a hull is covered by a special resin called gelcoat, which mainly protects it. Thus, this gelcoat...

Read more - October 12, 2022

The «Deadrise» of the hull and its importance

By the term of deadrise we mean the angle which is formed between the horizontal plane and the side of the hull, at its any point...

Read more - October 12, 2022

High Gear Ratio vs Low Gear Ratio

It is a fact that every manufacturer of outboard engines installs different gear ratios while we see that as the horsepower decreases the gear ratio gets higher...

Read more - October 12, 2022

The relationship of the Torque, Thrust and Gear Ratio

The torque that is produced by the engine is converted to thrust by the combined effect of the gear ratio with our propeller. Physics...

Read more