Testing a pair of 26″ Bravo I FS on a Skipper NC 100S with twin Verado 400R

Testing the HS4 4-blade and the Saltwater Series II 3-blade Yamaha’s propellers

Testing a pair of 26″ Bravo I FS on a Skipper NC 100S with twin Verado 400R

Testing the HS4 4-blade and the Saltwater Series II 3-blade Yamaha’s propellers

Four requirements your propeller should absolutely meet

Definitely, choosing the right propeller is not as easy as it may seem. Knowledge, experience, patience and of course several sea trials are required so as to be able to choose the most suitable propeller for our Rib.

After endless hours of testing, measurements and observations I can safely say that, among other things, the propeller we will finally choose for our boat must absolutely meet the following 4 preconditions at the same time:

1… to match with the characteristics of both our engine and hull at the same time.

This is one of the most critical requirements that our propeller has to meet. It has to match with the hull and the engine at the same time too, because otherwise, it is certain that either the boat’s performance will be poor or the good functioning of our engine will be undermined.

To make it clearer, our propeller must match with our engine’s horsepower in relation to its gear ratio and at the same time with the type, length and width of our hull.

We can not install any propeller on any engine but neither any propeller can push any hull.

There are restrictions defined by the horsepower and gear ratio of each engine as well as our own hull.

For example, in a low-horsepower engine or on a very fast propshaft, we can not install a «large» propeller, because the load on the propshaft and the gear will definitely be enormous. The larger (numerically) the gear ratio is, the bigger the propeller can be installed.

On the other hand, each hull requires a certain amount of thrust i.e. a minimum of propeller’s diameter to run efficiently. If our propeller’s diameter is smaller than the minimum required, then, even if we have the best propeller in the world, the performance will be disapointing and the slip’s values very high.

This is one of the most critical requirements that our propeller has to meet. It has to match with the hull and the engine at the same time too, because otherwise, it is certain that either the boat’s performance will be poor or the good functioning of our engine will be undermined.

To make it clearer, our propeller must match with our engine’s horsepower in relation to its gear ratio and at the same time with the type, length and width of our hull.

We can not install any propeller on any engine but neither any propeller can push any hull.

There are restrictions defined by the horsepower and gear ratio of each engine as well as our own hull.

For example, in a low-horsepower engine or on a very fast propshaft, we can not install a «large» propeller, because the load on the propshaft and the gear will definitely be enormous. The larger (numerically) the gear ratio is, the bigger the propeller can be installed.

On the other hand, each hull requires a certain amount of thrust i.e. a minimum of propeller’s diameter to run efficiently. If our propeller’s diameter is smaller than the minimum required, then, even if we have the best propeller in the world, the performance will be disapointing and the slip’s values very high.

2… to match with the mounting height of our engine.

Nowadays, there is a really great variety of well designed propellers and if they are properly used they can give us unique performance.

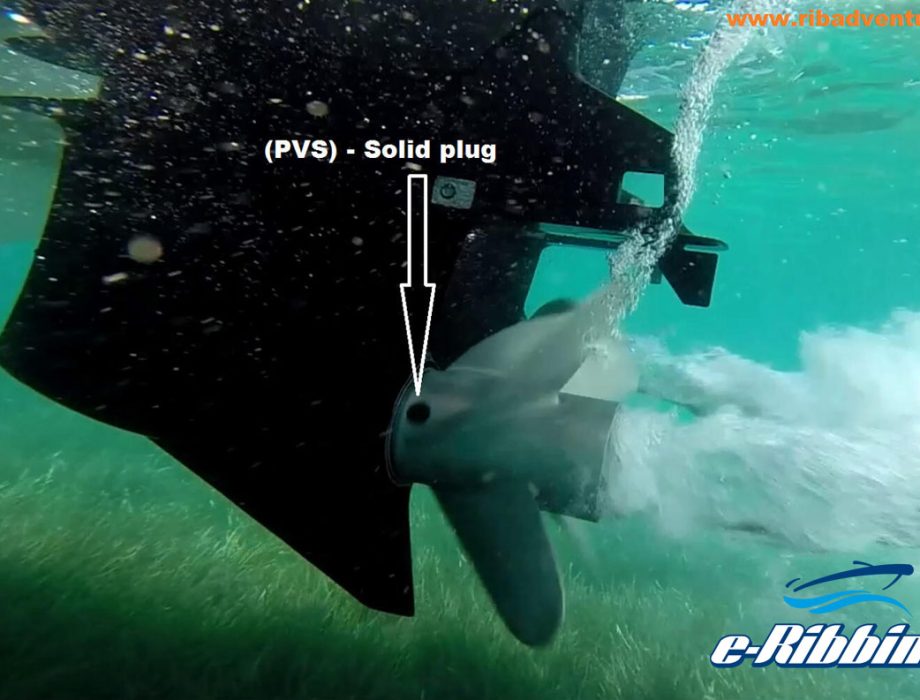

It is a fact that each propeller is designed to run at specific engine’s mounting heights. Other propellers perform better when running deeply in the water and others when running near the water’s surface.

So if we have a propeller that is designed to run near the surface and our engine is low positioned on the transom then will not get the maximum performance from that propeller.

Apart from the propeller design, however, there are some basic principles that define the engine’s mounting height in relation to the propeller we want to match.

Generally speaking, we should prefer higher engine’s positions for propellers with a larger diameter or larger overall blade area compared to smaller diameter propellers or propellers with smaller blade area.

3… match the use for which it is intended.

There is no propeller for any use, no matter how great designed it is. Each propeller is designed to perform better under certain circumstances and specific uses.

Some propellers are designed to achieve high top speeds, others to get the boat on plane faster, others to achieve high stern or bow lift, others for better fuel economy, and others to perform better at low and medium rpm.

But there is no propeller that can do it all together at the same time. So we have to choose our propeller according to our primary goal.

We will never be able to find the right propeller if we do not clear up what we exactly want to achieve.

For example: if our main goal is a general use of pleasure or travel, which is the vast majority of most cases, then using a propeller with the largest possible diameter and short pitch is the most efficient combination. Of course, in this case we will not get the higher possible top speed, but we will gain tremendous benefits at low and medium rpm, a range in which our engine operates most of time.

If our goal is to achieve the highest possible final speed then a smaller diameter and longer pitch propeller is the key of success.

Generally, propellers with large diameter and short pitch have great efficiency till almost 40 knots. After this speed, the large diameter and volume of the gearbox lead to excessive drag, which is mainly due to the change of water’s «behavior» at high speeds.

4… should allow the engine to reach; at least, the middle of the maximum rpm range recommended by its manufacturer, regardless the loads we are carrying.

If our propeller does not allow the engine to reach the maximum rpm range, or if our engine overcomes it, then its good operation is in danger, with a great risk of damages that usually cost very much.

We must keep in mind that when our engine does not reach its maximum rpm at WOT, it does not operate properly even at low and medium rpm.

Even if one of the above preconditions is not met by the propeller, there is no doubt that either the engine will not operate properly or the boat’s performance will be suffering.

In contrary, if the propeller fulfils all of the mentioned requirements at the same time then a great set-up will have been achieved!