Testing a pair of 23΄΄ Bravo I FS on a Corsair 31 with twin 250hp Optimax

Bravo I 15 ¼” x 26″ propeller on a Corsair 29 Racing powered by the new Verado 400R

Testing a pair of 23΄΄ Bravo I FS on a Corsair 31 with twin 250hp Optimax

Bravo I 15 ¼” x 26″ propeller on a Corsair 29 Racing powered by the new Verado 400R

Propeller Ventilation and Cavitation

Ventilation and Cavitation are two completely different phenomena that are observed, under specific conditions, during the rotation of the propeller and their understanding is often confused. Both the cavitation and ventilation of the propeller (except in certain special cases) have a negative impact on the performance of our boat.

Ventilation is the result of the entrance of air or exhaust gases from the exhaust outlet (they are drawn into propeller blades) between and around the propeller blades which lead to a sudden reduce of water load on the blades and thus to increase the engine’s rpm and the loss of its grip on the water.

This content is for Basic and Premium members only.

Read more Propellers

- November 9, 2022

ECO Enertia 16″ x 18″ vs Revolution 14 5/8″ x 19″

There is no doubt that both 3-blade ECO Enertia and the 4-blade Revolution are two of Mercury's most intelligently designed propellers which indeed claim the title of best...

Read more - November 9, 2022

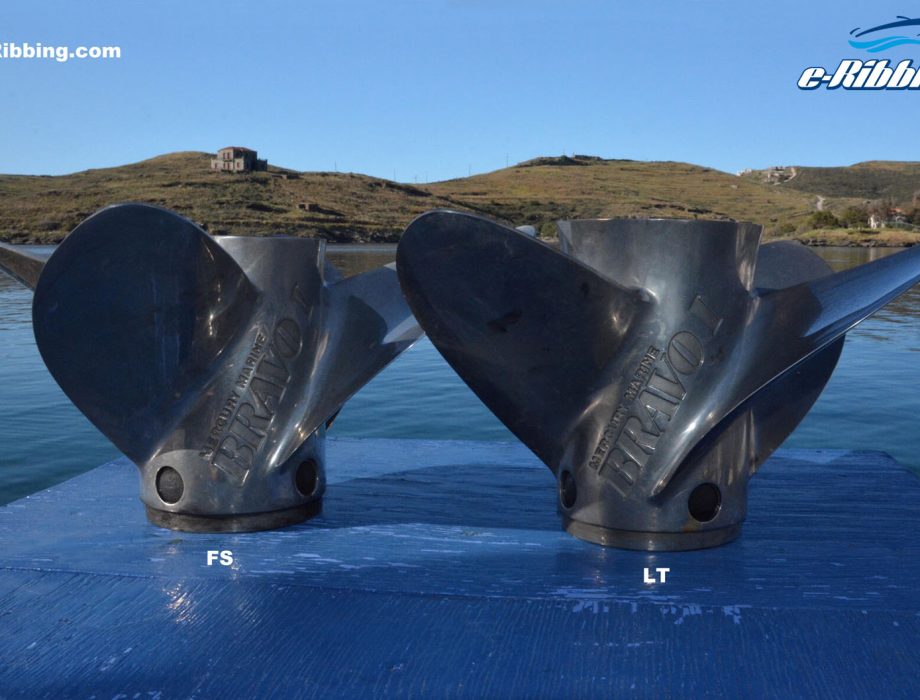

Comparing the Bravo I LT with the Bravo I FS propeller

Bravo I LT and Bravo I FS belong to the series of pro-finished Bravo I propellers, each one of which has undergone highly specialized modifications so as to match in specific uses...

Read more - November 8, 2022

Testing the HS4 4-blade and the Saltwater Series II 3-blade Yamaha’s propellers

The new HS4 4-blade propeller was launched in early 2017 and is designed for Yamaha outboard engines over 200 hp. With the addition of Yamaha’s Shift Dampener System...

Read more - November 8, 2022

Bravo I FS vs Bravo I XC propeller

During the Olympic 5.90 Speedster test, on the transom of which a Mercury four-stroke 150hp engine was mounted, we had the opportunity to compare two outstanding...

Read more - November 8, 2022

Four requirements your propeller should absolutely meet

Definitely, choosing the right propeller is not as easy as it may seem. Knowledge, experience, patience and of course several sea trials are required so as to be able to...

Read more - November 8, 2022

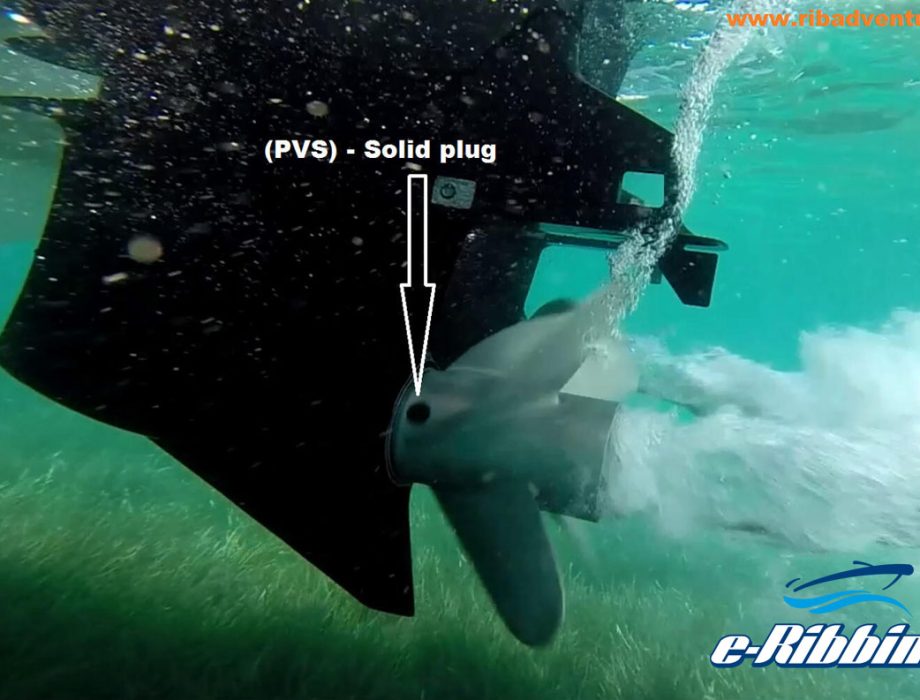

Propeller’s Performance Vent System (PVS)

The Performance Vent System, designed and patented by Mercury marine, is a management system of the exhaust gases that exit from the propeller's tube allowing us...

Read more - November 8, 2022

Testing a pair of 26″ Bravo I FS on a Skipper NC 100S with twin Verado 400R

It was the first time that two Verado 400R engines were mounted on the transom of the 10 meter Skipper NC 100S and therefore we didn’t know which propellers would fit better...

Read more - November 8, 2022

Hydromotive Quad IV 15 ½” x 27″ vs Signature Eagle 4 15″ x 27″

The new racing Pegasus RF 27 S of Top Line and a brand new Optimax 300 XS is a combination with which the Ribadventure team will take part in international races and...

Read more - November 8, 2022

Bravo I 15 ¼” x 26″ propeller on a Corsair 29 Racing powered by the new Verado 400R

It was the first time that on the transom of Corsair 29 Racing the new Mercury Verado 400R was mounted, a totally unknown combination for us. We tested the Bravo I 15...

Read more - November 8, 2022

Propeller Ventilation and Cavitation

Ventilation and Cavitation are two completely different phenomena that are observed, under specific conditions, during the rotation of the propeller and their understanding is often...

Read more - November 8, 2022

Testing a pair of 23΄΄ Bravo I FS on a Corsair 31 with twin 250hp Optimax

With the memories of the unforgettable moments Corsair 31 gave us against the huge waves of the Atlantic Ocean being fresh, I took my position behind its cockpit. However...

Read more - November 8, 2022

Testing a pair of 23΄΄ Revolution on a Technohull SeaDNA 999 with Twin 300hp Verado

Revolution is a 4-blade propeller, designed to run close to the sea surface and operate very well even with small amount of water, a fact that makes it perform very well in high...

Read more - November 8, 2022

Testing the Bravo I FS 15 ¼ ΄΄ x 23΄΄ and the Suzuki 16΄΄ x 21.5΄΄ propellers on a Sea Quest 7.60m rib with a Suzuki DF 225hp

Sea Quest is one of the best built and seaworthy ribs of the Greek market and is characterized by its particularly comfortable facilities and the impressive soft ride...

Read more - November 8, 2022

Testing the Trophy Plus propeller on a Larsen 4.95 RIB powered by a Suzuki DF 140 hp

The Trophy Plus is one of the most popular propellers of Mercury Marine, due to the very good features of its design.We tested the 23΄΄ pitch Trophy Plus propeller on a Suzuki DF...

Read more - November 8, 2022

The Trophy Plus propeller and its design characteristics

The Trophy Plus is a 4-blade stainless steel propeller by Mercury Marine which is available in a diameter of 13 ¾΄΄ and in pitch sizes: 17", 19", 21", 23", 24", 25", 26", 27" and 28 inches...

Read more - November 8, 2022

When your propeller doesn’t perform as you wish

It is a fact that the choice of the right propeller is often quite complicated since it depends on many factors, the understanding of which is often quite difficult...

Read more - November 8, 2022

Does the choice of the propeller affect our engine’s longevity?

It is known that the choice of the propeller directly affects the engine’s performance. But how many of us know that the propeller affects the outboard’s longevity apart from...

Read more - November 8, 2022

How does the pitch of the propeller affect the boat’s performance?

It is very well known that every change in propeller’s pitch has a direct effect on the performance of our boat. It is also known that each inch of the pitch «costs» 150-200 rpm...

Read more - November 8, 2022

Powertech LFS 4-blade 16″ x 21″ vs Suzuki 3-blade 16″ x 21.5″

Powertech LFS is a 4-blade propeller which is designed for Suzuki outboard engines and is ideal for the boaters who have installed a single powerful engine on their transom...

Read more - November 8, 2022

Comparing the Powertech LFS 4-blade 16″x 21″ with the Suzuki 3-blade 16″x 21.5″

Powertech for the last few years has presented the LFS 4-blade propeller which is available in a diameter of 16 inches and in pitch size from 17΄΄ to 23΄΄ in one inch...

Read more - November 8, 2022

Comparing the standard Bravo I with the pro-finished Bravo I FS

Standard Bravo I is a widely known 4 blade propeller with remarkable performance. It is available in diameter 15 ¼" and in pitch sizes:...

Read more - November 8, 2022

Bravo I FS 15 ¼΄΄ x 21΄΄ vs Revolution 14 5/8΄΄ x 19΄΄

As we have seen in another article, Bravo I FS was «born» from very specific modifications made to our known standard Bravo I propeller. Knowing the performance of Revolution 19΄΄...

Read more - November 8, 2022

Great secrets for the choice of the most suitable propeller

Certainly the choice of the right propeller for our boat is not something simple since it depends on a number of factors which in turn interact with each other to such an extent that...

Read more - November 8, 2022

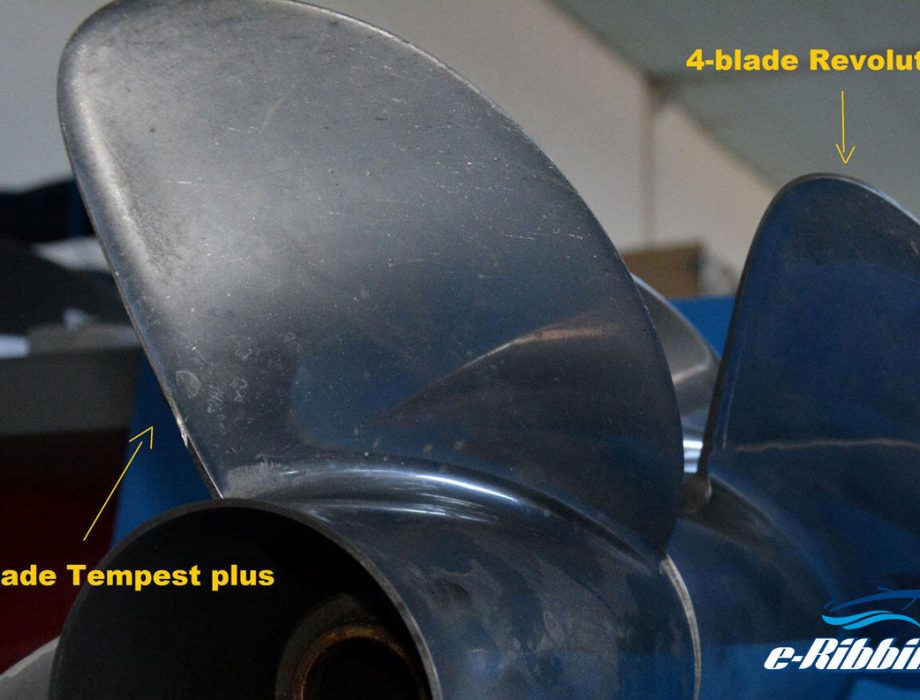

Comparing the Tempest plus with the Revolution

The Tempest plus is a 3-blade propeller that is designed for boats over 5 meters and recommended for outboard engines over 135hp. It is available in 17, 19, 21, 22, 23, 24...

Read more - November 8, 2022

Testing the Tempest plus 23΄΄ and the Revolution 21΄΄

Having in mind that the Tempest plus and Revolution match very well with the combination of Pegasus 20 with the E-TEC 175hp, we tested them in different pitches in...

Read more - November 8, 2022

Tempest plus vs Revolution

Tempest plus and Revolution are two well-known propellers with almost the same design, a fact that allows us to compare them each other and to draw safe conclusions...

Read more - November 8, 2022

Hydromotive 4-blade 15 1/2″ x 19″ vs Suzuki 3-blade 16″ x 18.5″

Testing the above propellers is a very good opportunity to realize once again that the type of our hull is the most important factor which defines the proper diameter propeller that...

Read more - November 8, 2022

Propeller slip and its role to the boat’s performance

As we are trying to explain how a propeller works, in most of the cases we compare it with a screw which enters into the wood. But in reality, the propeller operates in the water...

Read more - November 8, 2022

Hydromotive vs Eco Enertia

Facing one of the best well-designed ribs which is indeed characterized by its fast hull, and two of the best-designed propellers it was impossible to resist the temptation...

Read more - November 8, 2022

Revolution 19″ vs Revolution 21″

Revolution is one of the best designed 4-blade propeller which is recommended for engines above 200 hp. The large surface area of its blades, the aggressive cupping and the high...

Read more - November 8, 2022

Laser II 13 1/4″ x 25″ vs Revolution 14 5/8″ x 23″

In order this to happen however, the prop should match to the boat-engine combination and of course the type of the hull, its length and the total weight of the boat to enable it to...

Read more - November 8, 2022

ECO Enertia 16΄΄x 19΄΄ vs Suzuki 16΄΄x 18,5΄΄

It has been described as a "magical" prop, with excellent performance over the whole rpm range, while it also achieves very low consumption, as it is characteristically...

Read more - November 8, 2022

Enertia vs Tempest plus vs Revolution

There is no doubt that the Tempest plus and the Revolution are two well – known propellers which take the first place in the preferences of the skippers. Still, this doesn't...

Read more - November 8, 2022

Mirage Plus 14 5/8΄΄x 23΄΄ vs Suzuki 14 3/4΄΄x 23΄΄

One of the best known propellers for all around use, especially in the field of inflatable boats, is the Mirage plus. Its good performance in many different types of boats...

Read more - November 8, 2022

Testing 19 props in a day – part 2

Continuing the evaluation of propellers we made a summary of their performance at 4.500 rpm...

Read more - November 8, 2022

Testing 19 props in a day – part 1

At that morning we loaded 19 propellers in the small cabin of the Shearwater 860 which was powered by a single 300hp Suzuki outboard engine and headed to Serifos Island. Our aim...

Read more